5th February 2026

Another appalling day, weather wise. Let nobody tell you that this country is not that cold, even in winter. The constant wind, rain and freezing temperatures, tear through you like nowhere else. Just stepping outside feels like a punch to the face. It’s the damp you see. This country of ours is so wet most of the time, that when the temperatures plummet, we don’t experience the drier cold that others do and that makes it a bitter, miserable experience!

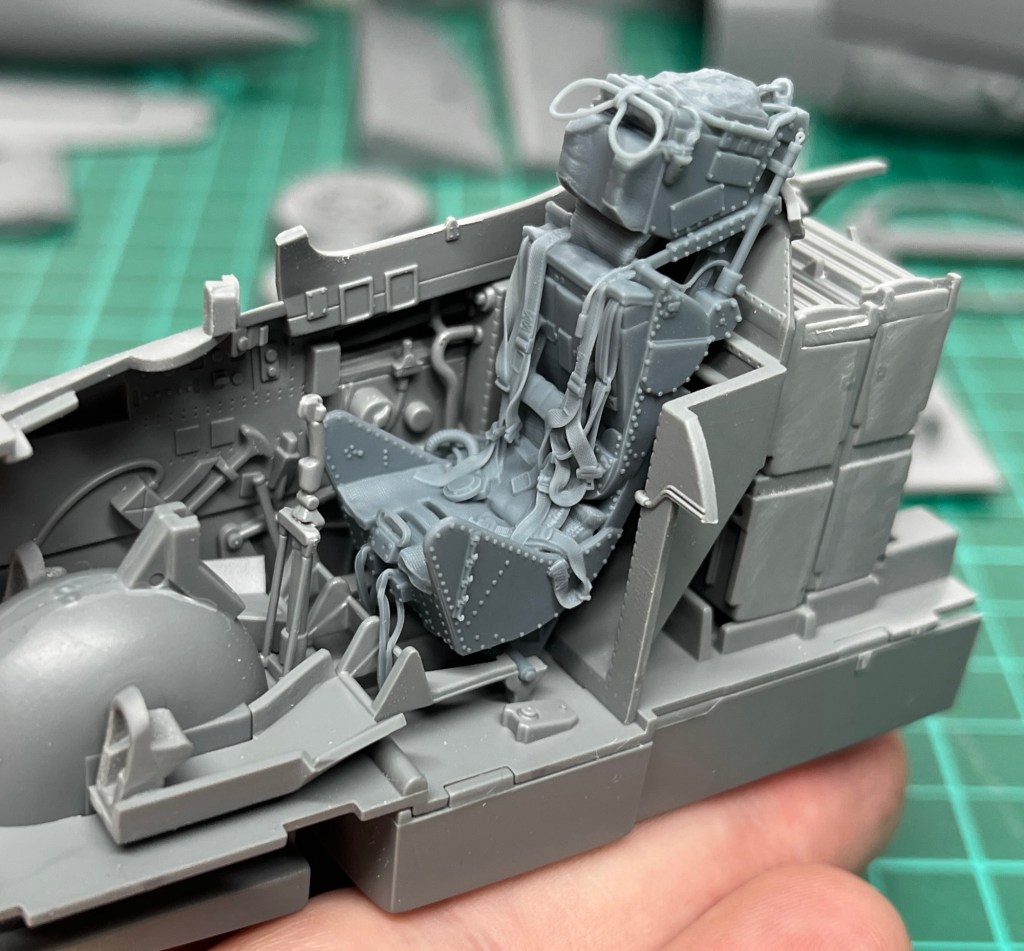

Hunkered down, I’ve spent today doing some more work on the Meteor, wrapping up basic construction ready for some additional details in the morning.

My main port of call was the cockpit. Though mainly built from the box, I’ve improved the image with the inclusion of a stunning 3D printed seat from ASK. Astonishingly well-detailed, this will be the highlight of my build and though I know it will take a long time to paint if all that detail is to be brought out, it will be worth it in the end!

This is where 3D printing comes to the fore, offering incredible detail with little to no construction. Sure, we have had updates for years now, but the details we are now seeing using this new medium is head and shoulders beyond what has gone before. Take this seat as a simple example. Just look at the natural sit of the straps and the delicate detail that they alone incorporate. I cannot think of any way you would ever be able to model and cast that using traditional methods, which is why printing these parts is now so exciting.

With an hour on the pickleball court first thing in the morning it will be a later start, but I plan on spending the rest of the day detailing one of the kit’s Derwent engines. Though nicely detailed from the box, my reference images showed some other features that I think could be added which I hope will make one of the engine bays, as detailed as that superb cockpit! Fingers crossed, eh?

See you tomorrow.

0 comments on “A MODELMAKER’S LIFE: 3D PRINTING FOR THE WIN…”